In 1978, ICI (the British chemical industry business) created PEEK (Polyetheretherketone). In the years that followed, it saw further development at companies including DuPont, BASF, Mitsui Optoelectronic Co., Ltd., VICTREX, and Eltep (United States).

As a type of high-performance polymer material, PEEK is distinguished by its low creep variable, high elastic modulus, outstanding wear resistance and corrosion resistance, chemical resistance, non-toxicity, flame retardancy, and the ability to maintain good performance even when subjected to high temperature/pressure. As well as high humidity under the poor working conditions.

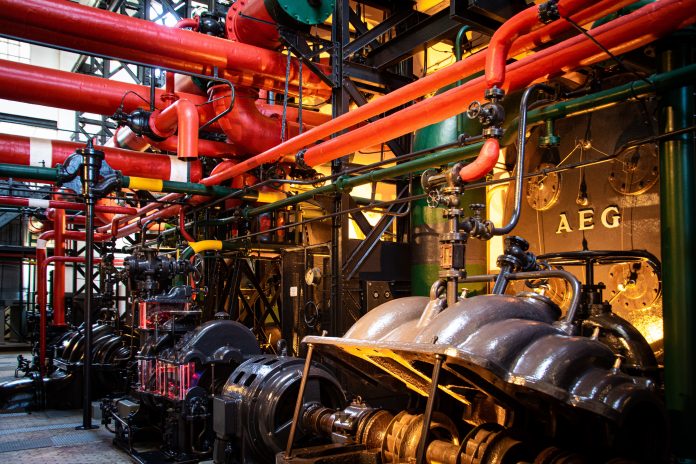

PEEK can be used for high-temperature and high-pressure valves such as those used by ball valves manufacturers, pump compressor valve plates, nuclear valves, piston rings, valves, and the core of a valve.

Table of Contents

Insights From PEEK Science

In terms of durability, PEEK Seals are among the best polymer seals on the market. Because of its excellent tensile strength and low load-induced distortion, PEEK is a material of choice for many applications. Therefore, PEEK machined seals are extremely long-lasting, even when subjected to extreme conditions.

Wear resistance, and mechanical strength are not compromised even at temperatures of 260 degrees Fahrenheit.

PEEK is the material of choice when durability and reliability are of the utmost importance. Extremely high strength, dimensional stability, and stiffness are combined with superior wear, chemical, and moisture resistance. PEEK is resistant to deterioration from corrosion, galling, or distortion, even when continually subjected to steam or hot water.

As a general-use material, unreinforced PEEK is exceptional in both elongation and durability. Carbon fiber-reinforced PEEK provides designers with the benefit of outstanding compression strength and stiffness and lower expansion rates.

Whereas glass fiber-reinforced PEEK provides enhanced strength, stiffness, and stability at high temperatures. A PEEK seat can be machined with high accuracy and they are used in countless applications.

Major Applications

Below are some common applications of PEEK:

- Components that slide and wear

- Food-safe components

- Gears

- Seats for valves

- Spares for pumps

- Parts of a structure

- Fixtures and fittings

- Components like bushings, bearings, seals, and rings

- In-and-out jacks

- Wafer carrier

- Industries

- Engineering that makes use of chemicals

- Mechanics, or the study of machines

- Business related to the production of energy

- Electronics

- Advanced cooking equipment

- The oil and gas sector

- Aerial vehicles and aeronautical engineering

- Business sector dedicated to automobiles

- Modern semiconductor engineering

PEEK Valves’ High-Demand Features

- Safe For Use Under Extreme Heat

PEEK resin has a high glass transition temperature of 143 °C and a high melting point of 334 °C. It is possible to reach temperatures of up to 260 degrees Celsius when it is in continuous operation. Also, the load thermal transformation temperature of a 30% GF or CF reinforced brand can reach temperatures of up to 316 degrees Celsius.

- Mechanical Strength

PEEK raw material resin possesses great fatigue resistance to alternating stress and good toughness and rigidity, making it comparable to alloy materials in terms of its toughness and rigidity.

- Resistant To Flames

The ability of a material to continue combustion after being ignited with a large amount of energy from a mixture of oxygen and nitrogen is what is meant by its flammability. This ability is described in the standards known as UL94.

The time it takes for a sample of a specific form to self-extinguish after being ignited in a vertical position is recorded. Fire tests on PEEK showed a v-0 rating, the highest possible rating.

- Stability

Some applications benefit greatly from PEEK plastics’ exceptional dimensional stability. PEEK components that need to be highly dimensionally accurate are immune to external factors like temperature and humidity. They are often used in the underwater pond filter systems where water interaction is the highest.

Due to the negligible shrinkage of PEEK plastic raw material during injection molding, the dimensional tolerance range of PEEK injection parts may be precisely controlled.

This result in a level of dimensional precision that is orders of magnitude greater than that of parts made from standard plastics.

- Minimal Thermal Expansion Coefficient

There is not much of a change in the dimensions of PEEK components when the temperature does vary.

- Strength In All Dimensions

Plastics’ dimensional stability in use or storage relates to how well they retain their original dimensions. The crimp in the chain segment is responsible for most of the ensuing dimension shift by increasing the activation energy of the polymer molecules.

- Superior Efficiency In Thermal Hydrolysis

PEEKS has a minimal affinity for water, even when subjected to extreme humidity and temperature. Common plastics like Nylon do not visibly expand or contract due to water absorption.

Read Also : Paying Municipal Taxes Online: A How-To Guide

Conclusion

PEEKs was invented in the last two decades and has since found widespread application in industries as varied as oil and gas, aerospace, automotive production, electronics, medicine, and the food and beverage industries.

PEEK’s superior performance in sealing applications makes it a top choice in a number of major sectors.

We hope you found this post useful in terms of PEEKs selection for your industry.